After about a year and a half of working in the engine shop, I had received enough training to have accepted more responsibilities and duties as an inspector in the process of engine repair. I inspected more complex parts that required a more measured approach with attention to detail. The chief inspector at the time tapped me to learn an inspection procedure which called for using a very specialized camera to be inserted into the engine to look for damage and potential problems.

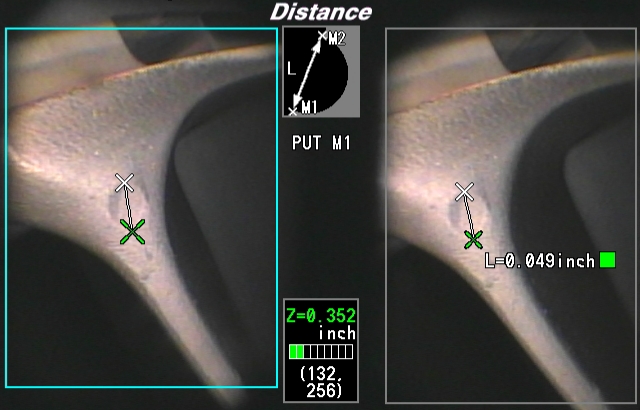

Borescope inspections required the inspector to search for damage within engines and determine if the damage is within a specific measured limit for continued operation. I watched the chief perform borescope inspections before and it seemed like something I could do, it was almost like a video game. It had a controller and a joystick, it made sounds and you had a mission while in control of the camera. The camera had the ability to see very close up so that we could identify the smallest damages and had the ability to measure thousandths of an inch to help determine whether damage was within limits outlined in the engine manual.

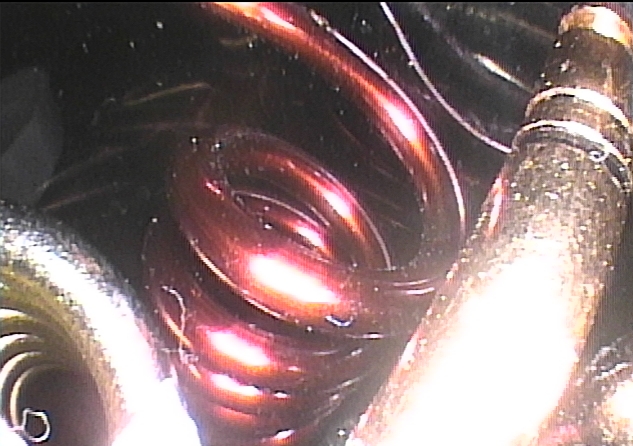

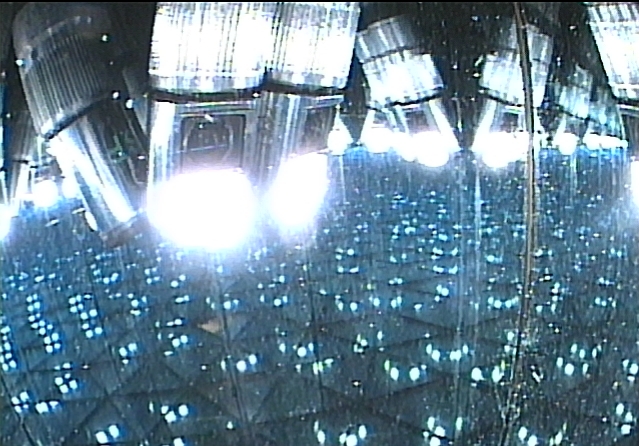

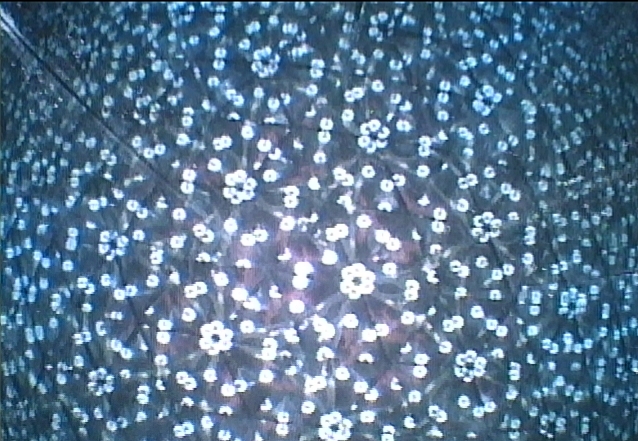

This ability to see things close up was incredible and sparked curiosity. What could I do with this thing that can’t be easily done with conventional cameras? There is no non-dirty sounding way to say this, so here it goes. I inserted it everywhere so I could to see what came out. The best results were from very reflective things. A buddy if mine had a jar full of old springs and hardware that made for some interesting compositions.

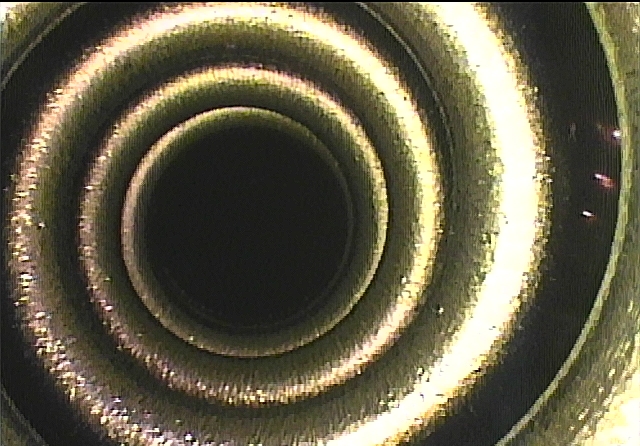

A kaleidoscope was also among my favorite subjects for this. I placed a side view lens on the camera tip and the camera took a selfie within the kaleidoscope.

It was was capable of many cool tasks and I’m glad to had the opportunity to play with such an expensive piece of equipment. Some very interesting images came from that time period.

After 18 more months of training, I was finally able to receive an FAA Repairman Certification through the engine shop. This meant I had an equivalent of an FAA Powerplant License and could sign off on inspections and release engines from inspection requirements while in service. It also meant that I would now face the same consequences that Value Jet contractors faced in the 90’s when the plane crashed in the Florida Everglades. That little fact did not sink on until much later.

Leave a comment