While working at the engine shop, I was able to see things that most people wouldn’t have the chance to. Jet engines being taken apart into smaller pieces in order to fix them and make them work again was a fascinating process. So much effort went into every aspect of the process that it would be difficult for most to see the beauty of an engine part that is discolored, or the mesmerizing repetition of an assembled disk and blade rotor as it spins, the mangled and distressed look of titanium from damage caused durig operation.

I saw these things and wanted to document them for source material, they became more than just imagery to use as reference. They stood alone in their appeal.

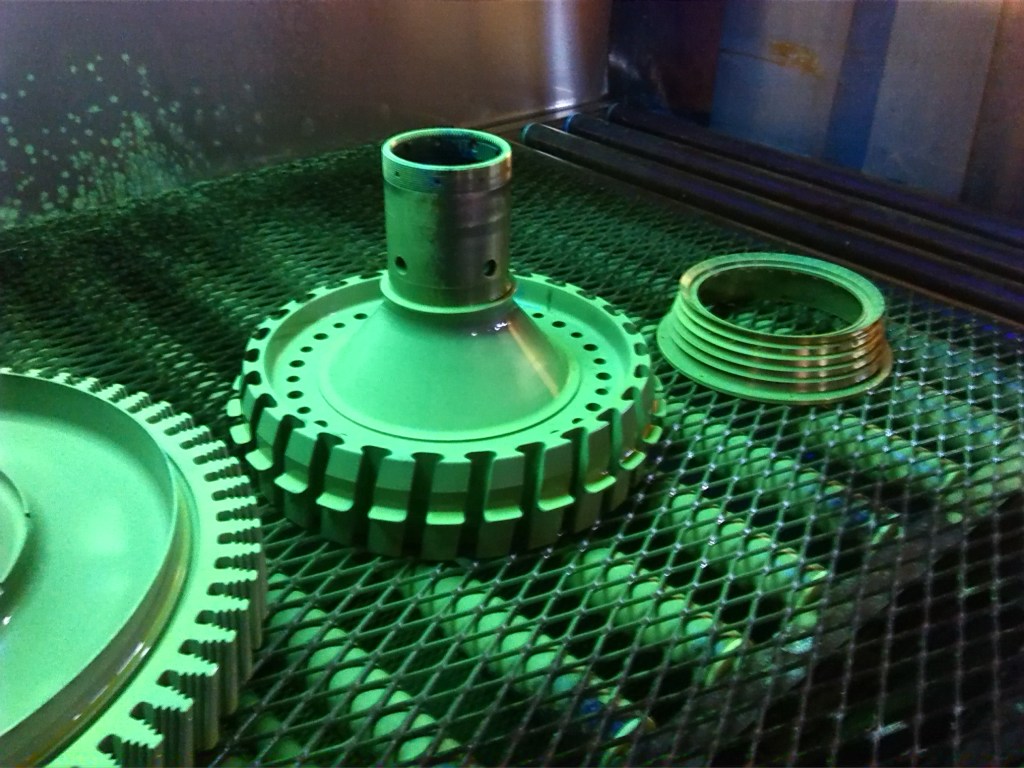

The individual engine parts underwent cleaning and repair procedures that altered their looks. Some were polished very well to remove certain blemishes before finishing the work with protective coatings.

Other processes involved specialized inspections to look for tiny cracks in metal, cracks that would otherwise be missed by the naked eye. A florescent liquid was applied to these pieces so that it could pool in a possible crack while the rest is washed off revealing the presence of a crack under black light. Anyone who knows me will tell you that this is my favorite green color, so naturally I was a moth to its light.

Other inspection methods required us to mark unfit parts for removal. I got creative with my markings and the repetitive nature of the job meant that a visual rhythm was achieved with any marking I placed on the parts. So I marked pieces with this in mind and created tiny compositions within engine parts before repair.

Simar rhythmic patterns could be seen on rotors which were being assembled. The assembly mechanic would mark the weight of each blade to make sure he installed it in a balanced pattern.

Protective coatings from parts that were removed from service for repair had a patina looking effect which differed wildly from one engine to the next. The patterns and colors came from the environment that the engine operated in. An engine operating in central Asia will experience totally different environments than one operating in the Caribbean. So you’ll get variation of colors in parts that show discoloration on their protective coatings.

There was clear influence of what I was doing as a job being put forth in the work I was making in the studio. The damage observed in the process of engine repair can be seen in pieces of the time.

There are photos from this rime period in the engine shop that I shouldn’t publish online over privacy concerns. The work that was performed here was, and still is, something to behold. All the effort that goes into making an engine able to fly again is reset every 8 years or so for these engines which need to be disassembled to replace protective coatings. It’s part of the reason that the aviation industry has moved on from this engine type. It is costly to perform this type of work so frequently when there are engine models with better efficiency and lower maintenance costs which does not always require the engine to be removed for repair. The MD-80 and the Pratt & Whitney JT8D powerplant are circling the drain being replaced by newer and better performing models. I’m sure that the process for repair of those new engines is full of similar quirks of beauty, but I’m also sure not many people will document it through the eye of an artist.

Leave a comment